What is a profile knife

A profile knife

is a specialized cutting tool used in woodworking and other industries to shape or profile a workpiece. It is commonly used in applications where precise and intricate designs or contours need to be created on the surface of materials such as wood, plastic, or metal.

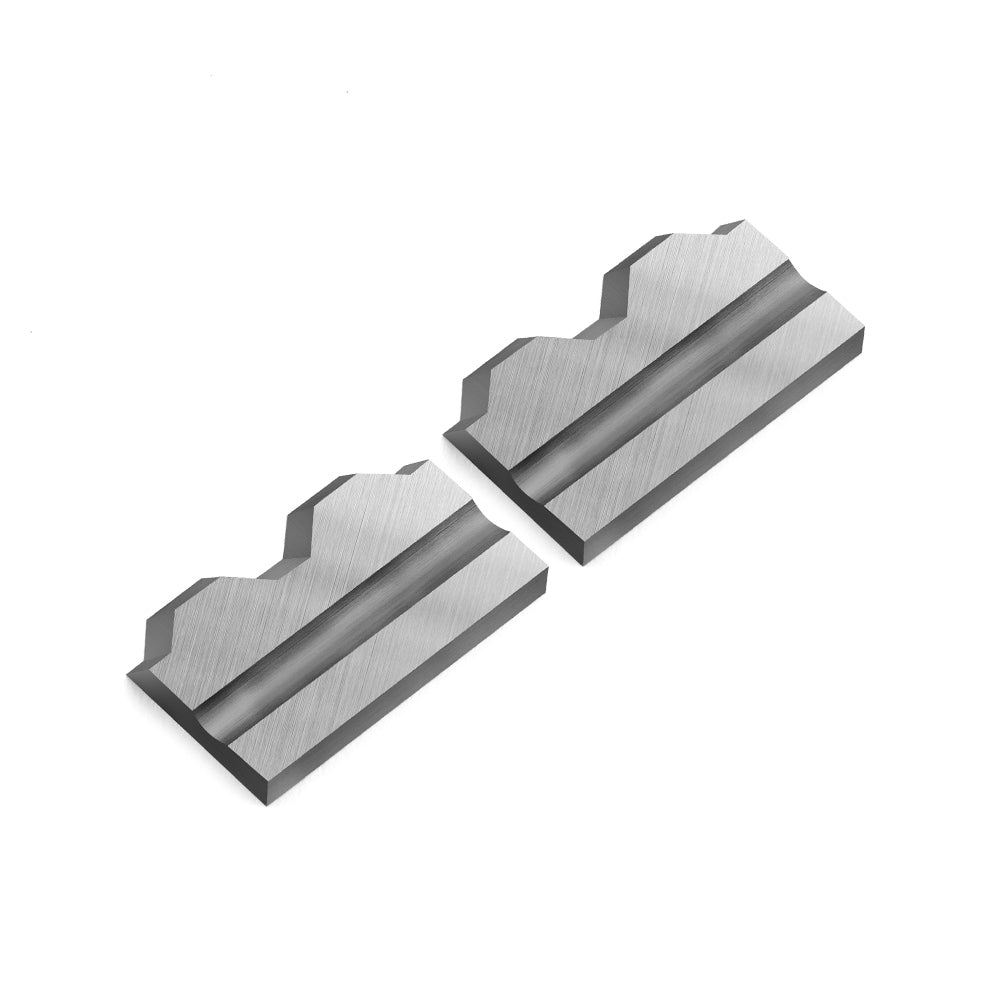

A profile knife consists of a steel blade or cutterhead with a specific profile or shape ground into its cutting edge. The profile is designed to match the desired shape or contour that needs to be replicated on the workpiece. The blade is typically mounted onto a machine, such as a shaper, molder, or router, which provides the necessary power and control for the cutting process.

The profile knife is guided along the workpiece to remove material and create the desired profile. The cutting action can be achieved in various ways depending on the machine and setup. For example, in a shaper or molder, the workpiece is fed against the rotating profile knife, while in a router, the knife is mounted on a spindle and the workpiece is moved against it.

Profile knives are available in a wide range of shapes and sizes to accommodate different applications. The profile can be as simple as a straight edge or as complex as a highly intricate design. Common profile shapes include round, ogee, cove, bead, chamfer, and many others. These profiles can be combined or customized to achieve specific decorative or functional effects on the workpiece.

tungsten carbide profile blank

The selection of the appropriate profile knife depends on various factors, including the desired profile shape, the material being worked on, and the specific application requirements. Manufacturers often provide catalogs or guides that showcase the available profile options and their recommended uses.

One important consideration when using profile knives is the quality of the blade material and its sharpness. The blade should be made from high-quality tool steel or carbide to ensure durability and long tool life. Additionally, regular maintenance and sharpening are necessary to maintain the cutting edge and achieve optimal cutting results. Dull or damaged profile knives can lead to poor surface finish, inaccurate profiles, and increased risk of tear-out or chipping.

Profile knives offer several advantages in woodworking and other industries. They allow for the replication of intricate designs and profiles with high precision and repeatability, saving time and effort compared to manual shaping techniques. They also enable efficient production of consistent profiles, making them valuable in mass production or batch manufacturing.

In addition to shaping and profiling, profile knives can also be used for edge trimming, chamfering, and other decorative or functional operations. They provide versatility in creating unique and customized designs on various materials, allowing craftsmen and manufacturers to unleash their creativity and achieve desired aesthetics.

However, it is important to note that working with profile knives requires proper safety precautions. The machines should be operated by trained personnel, and appropriate safety equipment, such as eye protection and dust collection systems, should be used to minimize risks associated with flying debris and dust.

In summary, a profile knife is a specialized cutting tool used in woodworking and other industries to shape or profile materials. It consists of a steel blade with a specific profile ground into its cutting edge. Profile knives offer precise and efficient shaping capabilities, allowing for the creation of intricate designs and contours on workpieces. With a wide range of profile options available, they are valuable tools for achieving decorative or functional effects in woodworking and other applications.

|